How does it work?

How HeatSave Works

Click an icon for more info

How does

it work?

Heating

Start Time

Turning on

the boiler

Boiler

Temperature

Flow & Return Balancing

Dry Cycling

How does it work?

At the heart of HeatingSave is a state-of-the-art microprocessor connected to a number of temperature sensors measuring the external outside temperature, room, hot water tank and heating flow & return temperatures.

At the heart of HeatingSave is a four layer, a state-of-the-art, surface mount microprocessor controller with 8 temperature/light level/humidity analogue sensor inputs, 8 occupancy sensor/switch digital inputs and 8 mains relay outputs. Each relay can switch the mains (10 amps max.) or distribute mains (6 amps max.). An additional contactor unit can switch up to 30 amps. Each controller can have up to 16 sub-controllers, each adding 8 analogue and 8 digital inputs and 8 relay outputs.

HeatingSave makes its savings by

- Accurately switching on/off heating systems using a heating diary.

- Using a unique “heat loss algorithm” comprising multiple quadratic equations for each heating zone (max. of 40 zones per controller) to switch the heating on as late as possible to still reach the required temperature by the required time.

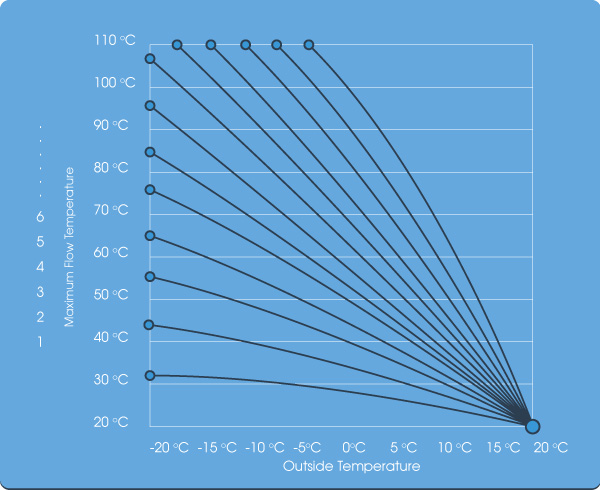

- Not over heating a building by applying adaptive outside temperature compensation using 12 different compensation curves that can be simply changed by the user.

- Occupancy sensors to reduce/switch off heating when nobody is around.

- Intelligently using the residual heat of a boiler rather than always switching it on.

- Intelligently applying frost protection, using pumps to distribute residual heat.

- Flow/return balancing so that the heating is matched to the boilers heat exchanger.

- Stopping dry-cycling.

- User “heat me now” buttons that revert back so the heating is not left on too high.

- User “boost” feature that degrades back to setpoint slowly so no sudden drop in temperature.

- Varying a room temperature set point automatically depending on outside weather conditions.

- Applying heat loss algorithm and variable heating patterns to immersion heaters + automatic anti-legionella function.

- Applying heat loss algorithm and variable heating patterns to air conditioning units.

- Control of solar-thermal collectors and/or biomass boiler with multiple heat-dumps.

- Electricity usage monitoring, billing/costing together with kWh’s and CO2 statistics.

- Solar PV electricity generation monitoring with graphs, kWh’s and CO2 saved.

The important point regarding the savings from the above features is that their effect is cumulative. So, a few percent here and few percent there soon adds up to over 25%, or more...

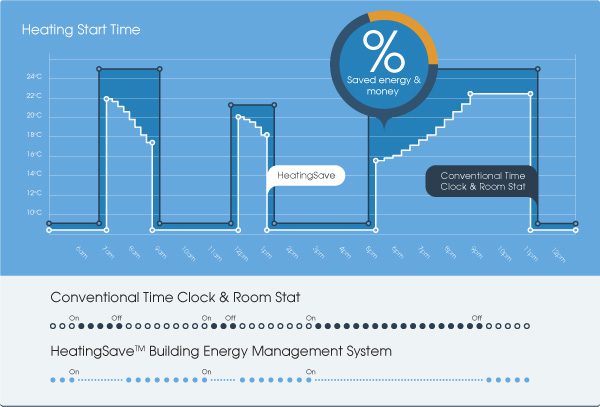

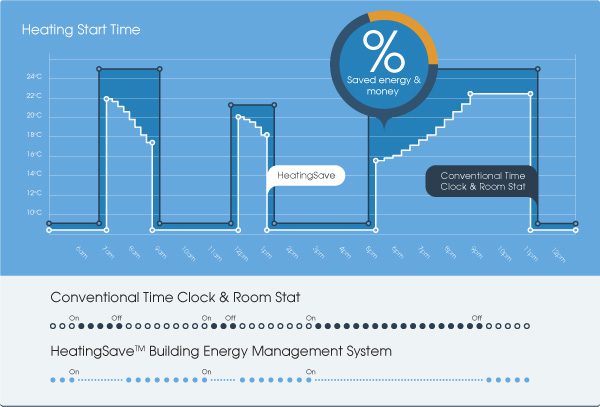

Heating Start Time

Traditional time clocks set the heating to come on at a particular time. Most are a `24 hour clock` and cannot vary the times throughout the week wasting fuel at weekends, often when the offices or buildings are unoccupied.

Even a 7-day clock cannot cater for bank holidays, holidays, shut downs or periods when the building is empty. With HeatingSave you can change a room temperature requirement over 1,000 times a day – yes, each day - giving you 100% control of the heating to meet your needs in summer, winter or throughout the year. The choice is yours!

This accurate method of matching heating to building usage keeps employees warm and saves the business money, between 10% and 30%+.

Almost all central heating boilers use time clocks to turn on the heating. Most are a `24 hour clock` and cannot vary the times throughout the week wasting fuel at weekends, often when the offices or buildings are unoccupied. 7-day clocks improve this situation, but cannot cater for bank holidays, holidays, shut downs or periods when the building is empty.

Despite the best will of owners of such systems who try to switch off the heating system when it’s not required, they are usually left on with owners/employees only releasing this when they next return to work.

Associated problems are

- Employees sometimes “fiddle” with the controls which exacerbates the situation further.

- The duty of care of employees to switch off the heating during period of inoccupancy is not as high as if it was their own heating system and they were paying the bill.

Each heating zone within HeatingSave (max. of 25 per controller) has a heating diary and a default heating pattern for each day of the week. A standard pattern can be entered for each day and exceptions only created as they occur. This is a simple thing to do either using the 16 character by 4 line backlit , “large character” LCD keyboard on the controller or at a PC. Up to 1,000 diary entries can be entered at each controller.

Each heating pattern can be changed every minute of the day. That’s 1,440 times a day – a bit excessive – but what it does mean is that the heating can mimic your exact requirements - giving you 100% control over the heating to meet your specific needs in summer, winter or throughout the year. The choice is yours!

Most importantly, this level of control means temperatures are set to suit the way in which business is run. No only can particular days have different work patterns to mimic the buildings’ usage, but you can enter/change settings as you know about them and leave HeatingSave to get it right on the day.

For example, you might have a conference room with variable occupancy. Sometimes it’s used a lot and then there are periods of no use at all. You probably diarize the usage on a computer, so when you are updating the diary on your PC you can also update the heating diary for the conference room at the same time. This is simple and easy to do. HeatingSave will then remember to change the heating pattern automatically.

Small changes to the heating pattern can make small but significant savings to the heating bill. This means that the heating can be warm in the morning when people first arrive and slightly cooler during the day when everyone is working. The HeatingSave rolling diary knows about weekends, shift patterns, holidays and shutdowns, so entries can be made to the heating diary in advance. This accurate method of matching heating to building usage keeps employees warm and saves the organisation money, between 10% and 30%+.

Turning on the boiler

Your current heating time clock turns on your boiler so that rooms are warm at a specific time. It does this irrespective of the outside temperature - because it doesn`t know it.

In winter, the outside temperature 1st thing in the morning can be -5°C on one day and +12°C the next, so HeatingSave calculates the “heat loss profile” of your specific building using the current outside and inside temperature to work out the absolute latest time to switch on the boiler for the rooms to be warm for when you want them. Equally, HeatingSave switches off the boiler early on warm days at the end of the heating period - saving up to another 8% of fuel.

Central heating time clocks turn on the central heating the same time every day irrespective of

- the outside weather conditions

- the residual heat within the heating zone or building

- the heat loss profile of the heating zone or building

Within HeatingSave each heating zone is managed independently; a heating zone defined as area within a building, a hot water cylinder(s) or even the whole building itself. The reason why time clocks cannot manage heating to this level is because they are dumb with no intelligence.

The problem is that the outside winter temperature at say 6am on a winter’s morning can be -5°C on one day and +12°C the next.HeatingSave has a mathematical algorithm (a series of quadratic equations) which have been designed to calculate and “learn” the heat loss profile of any heating zone. So long as the plumbing allows the control of the flow of heat into the zone, HeatingSave can calculate the heat loss profile of the zone. Armed with this information, the HeatingSave controller works out the latest time to switch on the heating for the given conditions, so as to reach the temperature you have set for a given time. In practice, HeatingSave will start the boiler later on warm days and/or if the zone has a large amount of residual heat, and starts the boiler earlier if the building is cold or its cold outside. The reverse happens at the end of a heating period. Here, heating to a zone is switched off early if the residual heat within the zone can be maintained at the required temperature until the end of the heating period.

As can be seen from the picture top right, the HeatingSave algorithm is learning and refining its decision making process every day its in operation, all the time keeping at the right comfort conditions whilst saving the maximum amount of heating fuel.

Savings made by the heat loss algorithm vary upwards from 8% of fuel used.

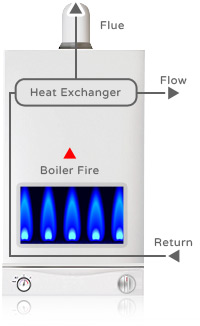

Boiler Temperature

Your boiler has a flow and return pipe carrying the heated water to the radiators and hot water cylinder(s). There should be several degrees difference between these for the heating system is working efficiently.

HeatingSave constantly monitors the flow and return temperature, adjusting the boiler temperature to keep the boiler running efficiently and avoid wasting fuel - savings up to 8%.

The chances are that the controls on your existing boiler are manual, with you turning them up in cold weather and down in warm weather; but you have to remember to do this (and be there to do it?) with fluctuating outside temperatures. In practice, nobody has time to alter the controls.

HeatingSave automatically performs the function of turning the boiler up or down. It’s called Outside Temperature Compensation. The boiler is automatically turned up in cold weather or at times of peak demand and turned down when it’s warmer. Each minute HeatingSave measures the outside and other temperatures to recalculate the mathematics and makes the necessary adjustments. In doing this, HeatingSave is using the buildings particular heat loss profile which it has been developing and refining since the day it was installed. Savings made through our outside temperature compensation are typically 10% or more, especially if outside temperature fluctuates, as seems to be the case with global warming.

Of course, it is possible to buy Outside Temperature Compensators from a variety of vendors. However, these

- usually only have one mathematical curve compared to HeatingSaves’s 12 curves

- are not integrated with other savings measures found within HeatingSave and are therefore less efficient

- are often almost as expensive as a complete HeatingSave system

Flow & Return Balancing

Your boiler has a flow and return pipe carrying the heated water to the radiators and hot water cylinder(s). There should be several degrees difference between these for the heating system is working efficiently. HeatingSave constantly monitors the flow and return temperature, adjusting the boiler temperature to keep the boiler running efficiently and avoid wasting fuel - savings up to 8%.

Boilers have a flow and return pipe connected to the heating system. This is called the primary circuit with the flow pumping the heated water to the radiators and hot water cylinder(s). The cooled water then exits the radiators and returns to the boiler via the return pipe. Inside the boiler is a heat exchanger which sits in the path of the hot flue gasses, absorbing the heat and transferring it to the water in the primary circuit. To work efficiently, there should be several degrees difference between the flow and the return.

If the difference between the flow and return temperatures is insufficient the boiler will still continue to try and heat the primary circuit at a faster rate than it can be absorbed. Boilers are unintelligent, so this will continue to happen until either the boiler thermostat temporarily reaches the required temperature or alternatively the room thermostat reaches its upper limit. Residual heat within the radiators will raise the temperature further, thereby creating an additional temperature overshoot. Under these conditions, fuel is wasted by attempting to force heat into the building faster than it can be absorbed.

HeatingSave counteracts the above problem as it measures the flow and return water temperature and only fires the boiler when the differential temperature exceeds a preset limit. This action matches the boiler heat output to the average heat transferred by the radiators. The boiler pump is kept switched on throughout to dissipate heat into the building. HeatingSave constantly monitors the flow and return temperature, adjusting the boiler temperature to keep the boiler running efficiently - savings up to 8% are possible.

Dry Cycling

Dry cycling occurs when the thermostat turns on a boiler for a very short time, not giving the boiler chance to fire up properly. This is because thermostats are dumb devices and have no idea of what they are connected to.Dry Cycling HeatingSave prevents dry cycling as it knows the operating characteristics of your particular boiler(s) and runs them efficiently, preventing dry cycling which wastes fuel and puts undue wear on the boiler.

Gas and oil heating boilers have a sequence of events that occur each time the boiler fires up. The purpose of this is to make sure that the flame is ignited safely each time. The first part of the cycle comprises safety checks and the boiler will abort the heating cycle if these fail. The next part of the cycle comprises the pre-purge time. During this further safety checks are made and the fan is turned on to vent any gaseous un-burnt fuel. This is most important as the wrong mixture of fuel and air (oxygen) can create an explosive mixture. Only when the pre-purge is complete does the boiler fire up. Even then there is no point in the boiler being switched off too soon as it will have had little time to absorb any meaningful heat into the heat exchanger. The time after this point we shall call the Meaningful Heating Point.

Normal time clocks and boiler controls can sometimes fire the boiler for a very short time, not giving the boiler chance to fire up properly. This is because they are dumb devices and have no idea of what they are connected. Dry cycling occurs when the boiler is started and switched for a time less than the Meaningful Heating Point.

HeatingSave prevents dry cycling as it knows the operating parameters of your boiler(s) and run it efficiently, preventing dry cycling which wastes fuel and puts undue wear on the boiler.

Immersion

Heater Control

Frost

Protection

PC Control

Automatic Occupancy

Fuel Usage

Room Set Point Matching

Immersion Heater Control

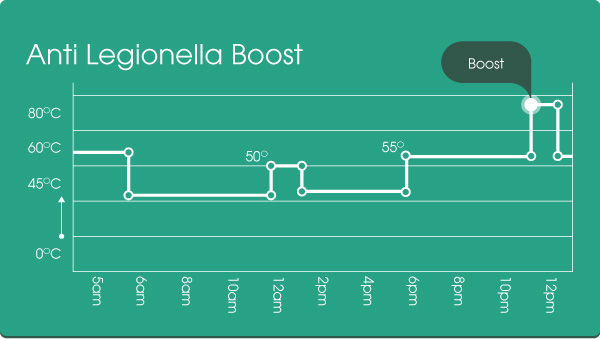

In almost all businesses the hot water immersion heater is timed to come on and off at certain times of the day. With HeatingSave, immersions demand is matched by the "heat profile algorithm" to use the least amount of energy – this time saving money on the electricity bill. Complete control over the hot water temperature also allows you to include a hot water “boost” to combat legionella. – again, this will happen completely automatically All this reduces the amount of electricity needed to heat the hot water - saving money at the same time.

Most businesses use hot water for hand washing and similar activities. Exceptions to this are industrial processes and residential facilities such as care homes and hospitals. In almost all cases the hot water immersion heater is timed to come on and off at specific times of the day at a specific temperature that is not easy to change. Just like boilers, immersions can’t switch themselves on later if it’s warm or when the hot water cylinder is almost up to temperature. The important thing to remember about hot water cylinders or calorifiers is that

- even the best lagged ones loose heat

- the higher the water temperature, the greater the heat loss

- immersions use the most expensive fuel (in cost and CO2 emissions), electricity

HeatingSave is intelligent, and switches on the immersion heater at the latest possible moment to get the hot water to the right temperature at the right time – this time saving money on the electricity bill. HeatingSave also allows you to set the water temperature differently throughout the day. It is important to match the use and temperature requirement of hot water to the time of day as this can save energy lost through the cylinder.

In residential buildings for example; 62°c for baths 1st thing in the morning, then 45°c during the day when water is only needed for hand washing or washing up, and back up to 58°c for showers/baths in the evening.

In commercial offices HeatingSave will save you money by automatically running hot tap water for handwashing at a lower temperature on warm days and hotter on cold days. This can be done automatically by turning on the zone to outside temperature compensation.

Complete control over the hot water temperature also allows you to include a hot water “boost” to combat legionella. – again completely automatically. All of these savings whilst small in themselves add up to a substantial amount over the heating year and can significantly reduce the amount of electricity needed to heat the hot water.

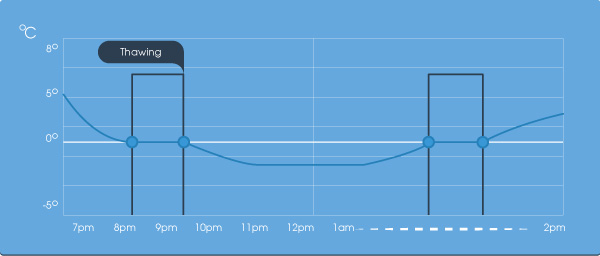

Frost Protection

Frost thermostats have the inherent disadvantages of thermostats and always switch on the heating. HeatingSave initially turns on the heating pump, distributing heat from one part of the building to another. Only when this is not enough will it switch on the boiler and then only using the minimum amount of fuel to keep the frost at bay - saving of 2%+ of fuel can be achieved.

Commercial premises protect against frost damage to the heating system and the fabric of the building by using frost stats. These usually turn on the heating when the outside temperature reaches 4°c. HeatingSave manages frost protection in a totally different way. The frost trigger point is variable and can be set by the user separately for each heating zone. The first action of HeatingSave is to switch on the heating pump and open zone valves for the areas affected. This allows the distribution of the residual heat within the building and can often be enough to keep the building above frost levels, especially if there is significant residual heat within the boiler and pipework.

To understand this further we need to remind ourselves of some basic secondary school physics/chemistry. To move 1cc of pure water from 2°c to 1°c requires the removal of approximately 4.184 joules of energy. To move 1cc of pure water from water at 0°c to ice at 0°c requires the removal of approximately 334.72 joules, some 80 times extra.

This extra removal of energy is just to change the state of matter from a liquid to a solid. (Because of its chemical structure water/ice needs more energy than similar substances within the same chemical period) The point is that for a frost to take place a significant amount of extra energy has to be removed from the heating system. This is why HeatingSave initially turns on the central heating pump and opens the valves to distribute heat from the warmer parts of the building to the colder parts. A frost threshold is quiet an energy jump and only when heat distribution is insufficient will HeatingSave switch on the boiler, and then only using the minimum amount of fuel to keep the frost at bay. The fuel saving of this type of frost protection over a standard frost stat can be 2% or more.

PC Control

HeatingSave can be connected to our advanced PC Software, delivering unrivalled control and monitoring of the system. From one PC you can control your entire building or whole network of buildings. Use remote control so you can login and get to any part of the system from any internet enabled PC. Software features include:

- Advanced planning of heating patterns and diary allowing 365 day programming with different patterns for each zone.

- Advanced graphing showing every temperature and on/off event ever recorded. Use these to prove temperatures at a given time or identify problems with boilers, pumps etc.

- Transaction logging and reporting. Get a number of alerts including boilers failing to respond, or when they unexpectedly start to increase in heat (manually overridden by someone). Also sensors hitting maximum/minimum temperatures are displayed. Avoid expensive repair and maintenance costs by determining what the problem is first so you can either change the settings yourself or send the right person first time.

- Running Costs – View the costs of boilers, equipment like pumps or immersions, air-cons etc. The costs are broken down by site or by each system individually. They are then displayed daily, monthly and quarterly. You can even see the carbon usage of your building or collection of buildings.

- View your site as a schematic with temperatures and equipment status overlaid. Keep track of an entire site from one easy view.

- Easily manage the settings and parameters for the entire system from one place.

Automatic Occupancy

Connect our infra-red occupancy detectors to the HeatingSave controller and the heating will automatically turn itself down when nobody is at work but automatically turn up the heating when employees arrive and need it. This means that HeatingSave is ideal for offices where the occupancy level can vary considerably. All of this happens automatically without you having to do anything – whilst HeatingSave keeps staff warm and saves money. Fuel savings for buildings with variable occupancy can be in excess of 20%.

HeatingSave occupancy sensors are based on Passive Infra Red (“PIR”) technology commonly found in burglar/intruder alarm systems. They work by detecting the frequency of infra red heat that is created by warm blooded creature such as humans. This beam is collected by a segmented mirror within the sensor to provide a definite trigger point as a person passes in front of the sensor. PIR’s can be connected in series or singularly and fed back to the HeatingSave controller where the frequency of detections is monitored. The user can trim the PIR sensitivity to suit particular applications so that the PIR’s work the way in which you want them to, that is to detect occupancy. An occupancy duration period during which time the heating will remain on stops the heating from oscillating between on and off.

Occupancy sensors allow HeatingSave to automatically turn the heating down to a background temperature when nobody is at work but automatically turn it up when employees are present. For offices, the room temperature can be held at a lower background heat and then automatically turned up when people arrive.

In care homes and other residential buildings the heating can be safely reduced in rooms/areas that are periodically used or for setting a lower temperature at night. Occupancy sensors are ideal for offices where the occupancy level can vary considerably as the whole process takes place automatically without the user having to do anything. This keeps staff warm and can make considerable saving on the fuel bill, in excess of 20%.

Fuel Usage

HeatingSave calculates the amount of fuel and electricity each day to prove to you the saving it can make over your existing heating control system.The longer HeatingSave has been installed, the more it saves as the microprocessor continually refines its mathematical thermal algorithm of your property. HeatingSave`s PC software displays how much your heating is costing - irrespective of the type of fuel used - even solid fuel. For those with oil-fired systems it predicts how much oil is left in the tank.

Automatic engineering facilities include

- Equipment fault reporting, such as a fault boiler

- Full data logging and event recording

- Interlocks for heating and cooling

- Service alerts that show when a heating service is due

- Automatic anti-seizing routines for valves and pumps not used within the last week

- Remote modem dial-in, dial-out facilities

- Internet connection

- Optional 0–10v output for mixing valve control and other proportional devices

- Automatic summer/winter heating year clock changeover

- Automatic BST/GMT clock change

The HeatingSave controller records the reading of each temperature sensor every minute and counts the total on-time for every boiler, immersion, valve, pump, air conditioning unit and light. This data can be analyses and reviewed by the HeatingSave PC package that comes with every system. Moreover, the PC software allows up to 22 simultaneous graphs to be viewed so that you can check that HeatingSave is saving you money over your existing time clock. It also calculates the amount of energy used and the cost for each day so that you can review energy expenditure as it happens, instead of months later when the fuel bill hits the doormat!

In this sense, HeatingSave performs all the functions of a “Smart Metering” system, but goes one stage further as it controls the energy usage instead of just reporting it. For those using heating oil it estimates the liters of fuel used each day and predicts how much oil is left in the tank. The data limits of each HeatingSave controller are listed below

- 5 boilers on a common flow, although this can be extended to 10

- 1,000 heating diary entries

- 50 PIR’s

- 25 pumps

- 80 temperature or light level sensors

- 25 valves

- 25 heating zones

- 10 immersion heaters

- 10 air-conditioning units

- 12 sub-controllers for each HeatingSave controller

- 50 heating patterns

- 50 switches

- 80 lights or sounders

- 30 intruder zones

- 5 solar heating systems

Up to 64 HeatingSave controllers can be connected on the network with an infinite number of networks.

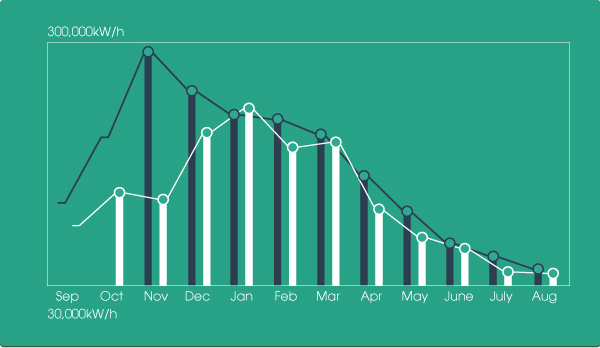

The graph on the right is a schematic to show the times of year when HeatingSave make the most savings. Firstly, is autumn.

This is because many traditional systems switch on the heating on the 1st October irrespective of the weather conditions.

The planet is much warmer at this time of year and so are buildings. Therefore, less heat is required to keep warm.

The next saving period is spring as warm days might not need so much heating, although traditional heating systems will still be blazing away. Finally winter and then summer. However, HeatingSave can make considerable savings on immersion heaters during the warm weather.

Automatic engineering facilities include

- Full data logging Temperature readings, light level readings and event recording of digital inputs such as switches and PIR’s and relay outputs of boilers, pumps, valves, air conditioning, immersions, fans, lights and sounders are stored by each HeatingSave controller in its 4Mb of SPI FLASH memory. These transactions are collected by the PC software and stored in a MicrosoftTM Sequel Server database where for larger systems it is not uncommon to have millions of transactions.

- Fault reporting HeatingSave reports boilers that fail to ignite, sensors that fail and other engineering faults and events to better manage the heating system and for engineering staff to take remedial action.

- Service alerts and warnings Alarms can be set for each temperature sensor so that alerts occur at the PC. The typical limits are maximum & minimum temperature readings and “fire” warning alerts. This is usually used if the reading is so high that there is a risk of fire. Later versions of the software allow email and phone text alerts if these limits are exceeded. The telephone service module and associated PC hardware allows the user to dial-in using a phone. Here, the speech computer talks the user through the alarm conditions and allows them to manually control the system via the phone keypad.

- Automatic anti-seizing This feature auto detects valves and pumps that have not been used for the past 7 days. For each of these, HeatingSave test opens and closes the valve and tests the pump. The purpose of this action is to prevent equipment failure after long periods of not being used. Special routines also exist for twin pump systems on a common flow.

- Modem Each HeatingSave controller has a modem connection independent of the RS485 network that is used for connection to other HeatingSave controllers and the optional PC infrastructure. This is particularly useful for stand-alone systems in remote locations that still require checking and setting from afar. A telephone point and a simple modem is all that is required to dial-in.

- Interlocks Digital input interlocks and similar relay interlocks inhibit HeatingSave so that heating and cooling cannot take place at the same time. This meets the requirements of the Carbon Trust.

- 0–10v output Most applications only require on/off controls for boilers, pumps valves and other outputs devices. However, some systems need a variable voltage (or current) output for mixing valve control and some types of boiler. HeatingSave provides for this using an additional hardware module and software interface.

- Summer/Winter changeover Each HeatingSave controller holds the start and end dates of the heating year, if applicable. The changeover between summer and winter is automatic, giving automatic changeover to immersions in summer if required. Equally the BST/GMT hour change is automatic too.

Room Set Point Matching

Room temperature set points are matched by the "heat loss algorithm" to automatically compensate for unusally warm or unusally cold days in spring and autumn.

The notion of whether a person feels too hot or too cold is not simply a matter of the temperature. For example, in Scandinavia people sit in a sauna and then break the ice on a lake to jump in it. They do not suffer from hyperthermia or even feel cold. This is because their core body temperature is high compared to the ambient freezing conditions.

Equally, in the UK a room at 19.5°c might feel too cold in winter when it’s cold outside and your body core temperature is low, but might feel too warm on a sunny autumn day when your core temperature is warmer. The important factor is to match the outside temperature to the heating zone. HeatingSave does this by automatically varying the zone setpoint to the outside temperature. The user can vary the rate at which this is applied to each heating zone so they can balance this effect. This might sound complicated, but in practice from the systems we have installed, this setting is only made once and thereafter HeatingSave keeps everyone at just the right temperature whilst conserving as much fuel as possible.

Tampering with

the Controls

Old-Fashioned Thermostats

CoolingSave

Management of Electricity Usage

Solar Hot Water

Water Usage

Tampering With The Controls

In some organisations employees adjust the heating controls and waste fuel.

This is what happens .......

- The employee feels cold and turns up the heating thermostat

- Instead of making a small adjustment, they turn it on full

- and - when they get too hot, they open the window?

If this sounds a familiar problem for you, then HeatingSave is perfect for your building. Firstly, you can set HeatingSave to get the temperature right so people don’t feel too hot or cold. Secondly, the employee interaction device allows employees to request temperature changes, but allow the "heat loss algorithm" to do this in the most efficient manner – keeping the employee at the right comfort temperature - and saving money. (plus CO2 emissions too). The HeatingSave controller is tamperproof with password protection to the settings and a separate password for the supervisor function.

HeatingSave has a number of features to prevent employees from adjusting the heating controls and leaving them in setting that can waste fuel. The keypad and display on the front of the controller has two levels of password protection. These passwords can be changed by authorized personnel locally or centrally using the PC software. The password programming meets the requirements laid down by the Carbon Trust.

The PC software is user ID and password protected too.

Quite genuinely employees need to have a method by which they can request the heating within a zone to be changed if they feel too hot or too cold. The important point here is that this needs to be a self correcting situation so that if employees feel too hot after requesting the raising of the temperature, they do not resort to opening the window to cool down. HeatingSave manages this situation by firstly getting the temperature right so people don’t feel too hot or cold. If employees do feel too cold, they can hit a button to increase the room temperature. The heating will be turned up for a while BUT will then automatically turn back – keeping the employee at the right comfort temperature - and saving the employer on their fuel bill.

Old-Fashioned Thermostats

The chances are that you have these both on your boiler and in your rooms and offices. They are crude devices often based upon an expanding piece of metal.

The difference between a thermostat (even if you have a modern digital one) and HeatingSave is that HeatingSave accurately watches the climbing room temperature and switches off the heat, using the residual heat within the boiler, to reach the correct room temperature. Thermostats can`t do this and always overshoot the temperature wasting fuel and sometimes causing discomfort. Thermostats also oscillate greater around the desired temperature causing more fuel to be used than is necessary. - savings up to 5% of fuel.

Most of the thermostats and boilers in the UK have these. They are often crude devices, based upon a bi-metal strip with two pieces of metal with different coefficients of expansion welded to each other. As they warm up one expands faster than the other. Put a set of contacts on the end and you have a switch that goes on/off depending upon temperature. A great device invented over 100 years ago and still used today.

Unfortunately, thermostats are only accurate to a point and even the modern digital ones, which use similar heat sensing electronics to HeatingSave, only measure the temperature and are unable to think or look ahead.

HeatingSave accurately watches the climbing room temperature and switches off the heat, using the residual heat within the boiler, to reach the correct room temperature. Thermostats can`t do this and always overshoot the temperature wasting fuel and sometimes cause discomfort. Thermostats also oscillate greater around the desired temperature causing more fuel to be used than necessary. Saving of up to 5% of fuel used is made by HeatingSave over traditional thermostats.

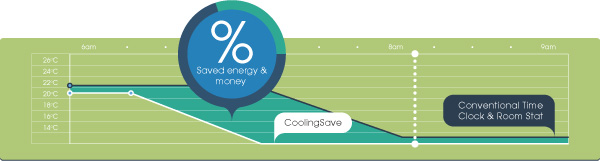

CoolingSave

The HeatingSave heat loss algorithm can also be used to control air conditioning units in summer. Just like heating, you choose the temperature you want and when you want it and HeatingSave will do the rest automatically, calculating the latest time to switch on the air conditioning to keep cool in summer. Room occupancy sensors may also be used; this time to vary room temperature. The savings with “CoolingSave” are reductions in the electric usage and electricity bill.

Each HeatingSave controller can manage up to ten air conditioning units and each heating zone can be cooled using an air conditioning system. HeatingSave applies the heat loss algorithm in the same way as it does for heating a zone and will work out the latest time to switch on an air conditioning unit to achieve the required temperature at the required time.

Simply allow HeatingSave to power the air conditioning from one of its spare relays and set the aircon to the lowest setting. HeatingSave will then take over, maintaining the cooling pattern you have set. More importantly, occupancy sensors can be used to allow the temperature to drift upwards when nobody is around and then to cool the area when it is occupied.

Just as with heating, the zone setpoint can be made dependent upon the outside temperature, so that on hot days the cooling is greater than on cooler days when the aircon is not so important.

Management of Electricity Usage

HeatingSave can save you even more money, this time off your electricity bill by better managing and controlling your electricity usage.

The HeatingSave meter counter receives pulses from electric meters to monitor kWh usage, minute-by-minute. We can also supply and install our own inexpensive meters which produce 1,600 per kWh of electricity used. Email or text message alerts can be sent when unusual electricity usage or demand is encountered, so that you have 100% control of electricity usage – as it happens – enabling you to take immediate remedial action.

The HeatingSave electricity billing system lets you account for and charge for electricity used. This is ideal for tenanted offices or billing individual departments for the electricity they use.

HeatingSave can install Solar PV systems under the Government accredited MCS scheme. Here, a HeatingSave system can be used to manage and monitor the electricity generated.

Solar Hot Water

Built into HeatingSave is the ability to control solar panels (flat panels or the more efficient glass evacuated tube type) and use these to heat or pre-heat hot water cylinders. Multiple configurations of panels ranging from those in a southerly position to east/west configurations can be managed by HeatingSave. Temperature sensors are placed within the panel (or panel flow), on the return and within the zone to be heated. HeatingSave uses these to control when the solar circulation pump is switched on and off.

Up to four “heat dump” zones are managed by HeatingSave. These typically will be hot water cylinders, (one or two coil types), heat stores, swimming pools or even a heated towel rail. Provision is made for a changeover control valve on each zone so that heating priorities can be set depending upon the amount of solar radiation available.

Unlike simple solar panel controllers, HeatingSave provides automatic control of the resulting hot water by directing it to either the hot taps or as pre-heated water into a secondary cylinder.

Water Usage

When pulse generating water meters are installed at the rising main or throughout a site, HeatingSave uses it meter counting unit and PC software to monitor and cost the number of litres used.

Minute-by-minute transactions allow water usage to be analysed and graphed. We can also supply and install our own water meters or use pulses from existing meters. Email or text message alerts can be sent when unusual demand is encountered, so that you can take swift action to control leaks or when taps have been left on.

Lighting Control

HeatingSave allows you to install our light level sensors and connect these into spare temperature sensor sockets on the existing HeatingSave system. Two types of light sensor are available;

- Outside light level sensors. These monitor when it gets dusk, dark, daybreak or daylight. They have in effect four trigger points that you can either set yourself at a particular point in time/light level or enter as a number at the keypad to approximate to a lux level.

- Inside light sensor. These measure internal lumessence. Again, there are four trigger points for detecting thresholds typically for minimum lighting levels in offices, factories and workshops.

Light level sensors can be used in conjunction with occupancy sensors (existing or additional) and light switches to

- turn on/off lights automatically

- save up to 50% on electrical consumption

- extend lamp life with lower maintenance costs

a wide range of switching options can be programmed into the simple & easy-to-use configuration

- Four stages of light level within each zone of 80 zones

- Occupancy and light levels in each zone

- Occupancy and timed delay off

- Switch on and timed delay off

- Light level on and off at daybreak

- Light level on (but not after a certain time) and off after a time interval

- Remote switching via PC or phone

- Volt-free contacts for linking to 3rd party Building Management Systems

- Variable time-delays from 1 second upwards

- Instant status indication at the controller or on the PC display panel

Each light or zone of lights is connected to a HeatingSave relay. A 30amp contactor unit is available for switching large loads. All types of lighting can be controlled including fluorescent, SON, metal halide, floodlights or security lights. A maximum of 80 lights can be programmed per HeatingSave controller. Apart from the different actions that can take place, of which the above are but a sample, you can program different actions if an area has the intruder alarm set or unset. This means addition lighting can automatically turned on when an area is more vulnerable. HeatingSave keeps track of the lights (and other electrical apparatus) it turns on and the duration, calculating on a day-by-day basis the kilowatt-hours used, the cost and the notional CO2 produced using the Carbon Trust conversion factors.

Access Control

Off-the-shelf Access Control products manufactured by Tensor plc seamlessly interface with the HeatingSave network to create a Building Security Management System. With the products working together, the system is able to be configured to automatically adjust the heating levels when people access particular areas of a building. This combination of security & energy management provides extra peace of mind knowing your heating system is only being used when necessary.

Zigbee

Zigbee is a wireless mesh network international standard for home automation and energy management, and is set to revolutionise the way in which future products will “talk” to each other. Attractive as it is from an installations view point, Zigbee however is not a panacea for every installation. Cable based systems are safer from a security view point and are not as easy to “get at” by would be malicious people or organisations. However, Zigbee is a great way to deploy systems where cabling would be expensive or awkward, or where the device’s location is not fixed. If you are looking for a swift and simple installation where pieces of equipment just “find” each other on a network the Zigbee is a serious contender.

Tensor plc is a member of the ZigBee Alliance. The latest HeatingSave controllers have Zigbee on-board and can deploy the ZigBee protocols. You can have much or your HeatingSave setup based around Zigbee or a mix & match type system with part of it cabled and part Zigbee based. Tensor manufacture or supply Zigbee based occupancy sensors, relay units for pumps, valves and other devices together with temperature sensors, humidity sensors, smoke detectors, light switches and security devices such as magnetic contact switches. The entire network can be visualised via a computer network or the web.